Figure 4 Materials Selection Guide

RUBBER-65A BLK

Mid tear strength production-grade rubber

RUBBER-BLK 10

Durable, hard rubber-like material

Figure 4 FLEX-BLK 20

High stability, durable and flexible plastic

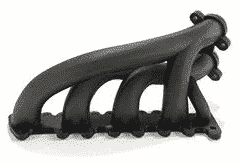

Figure 4 HI TEMP 300-AMB

High temperature resistant translucent plastic with HDT over 300 °C

Figure 4 EGGSHELL-AMB 10

Process-optimized material for sacrificial tooling to cast silicone

Figure 4 PRO-BLK 10

Production-grade, rigid material for production parts

Figure 4 TOUGH-BLK 20

Strong material with long-term environmental stability

Figure 4 MED-AMB 10

Rigid, translucent material that can be sterilized and tested at high temperature

Figure 4 FLEX-BLK 10

Flexible and durable, production polypropylene-like material

Figure 4 ELAST-BLK 10

Rubber-like, design elastomeric material

Figure 4 TOUGH-GRY 15

Economical, production rigid gray material

Figure 4 TOUGH-GRY 10

High speed, production rigid dark gray material

Figure 4 Rigid White

Opaque rigid white production-grade plastic

Get Started

Fill out the form below to get started