Selective Laser Sintering (SLS)

Let ATAG Incorporated expand your manufacturing capabilities with production-grade nylon materials to produce tough, functional complex parts with excellent surface finish, resolution, accuracy, repeatability.

SLS printers print in thermoplastic materials designed to offer you the full range of capabilities and isotropic properties, from rigid to elastomeric, high elongation, high impact strength, and high-temperature resistance. Get your parts in as little as 2 days.

Overview

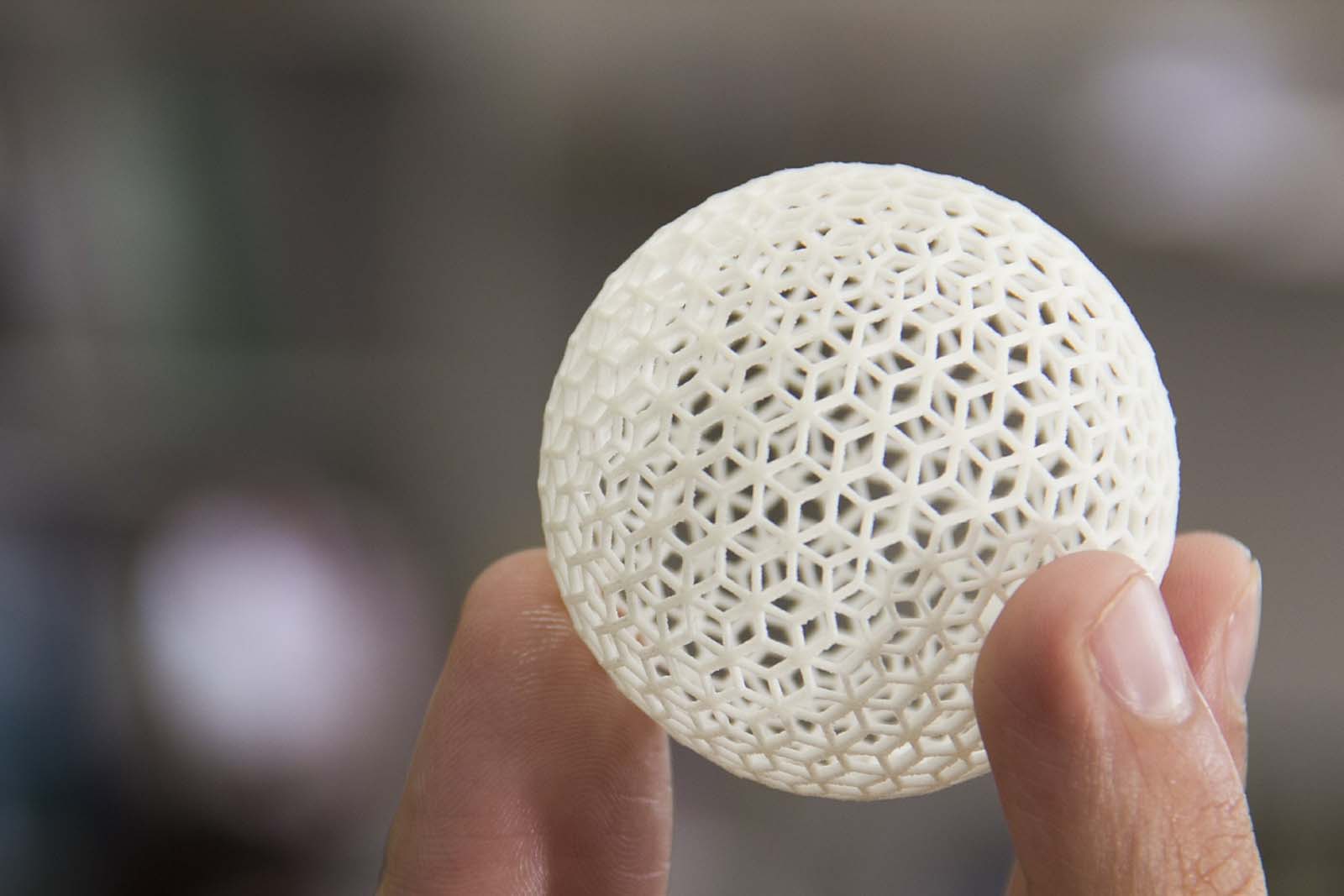

Selective laser sintering (SLS) is a powder-based 3D printing technology that uses a laser to fuse material layers into a final part.

After the laser traces a cross-section of the CAD design(s) onto a material layer, the build platform lowers and another layer is fused on top. The build platform continues to lower until every layer is built and the part is complete.

The completed 3d printed parts are then excavated from the build powder and further cleaned by bead blasting.

Robust, performant parts

SLS technology produces tough and durable parts that excel in high-performance prototyping and end-use applications. We utilize 3D Systems DuraForm SLS materials that have been optimized, validated, and tested to ensure quality, with uniform 3D mechanical properties. We also offer materials from other suppliers on request such as those from Windform and ALM.

Cost effective and reliable

With SLS we can repeatedly and economically 3D print functional end-use parts with high resolution in a broad range of thermoplastic, composite and elastomeric materials.

Consistent, durable parts

Our customers count on this process for the toughest applications, year after year. SLS offers far superior living hinges, snap fit and other mechanical joints than any other technology. With the broadest range of materials available, SLS consistently produces strong parts with high thermal and chemical resistance. SLS is the most economical thermoplastic solution for large quantities of parts.

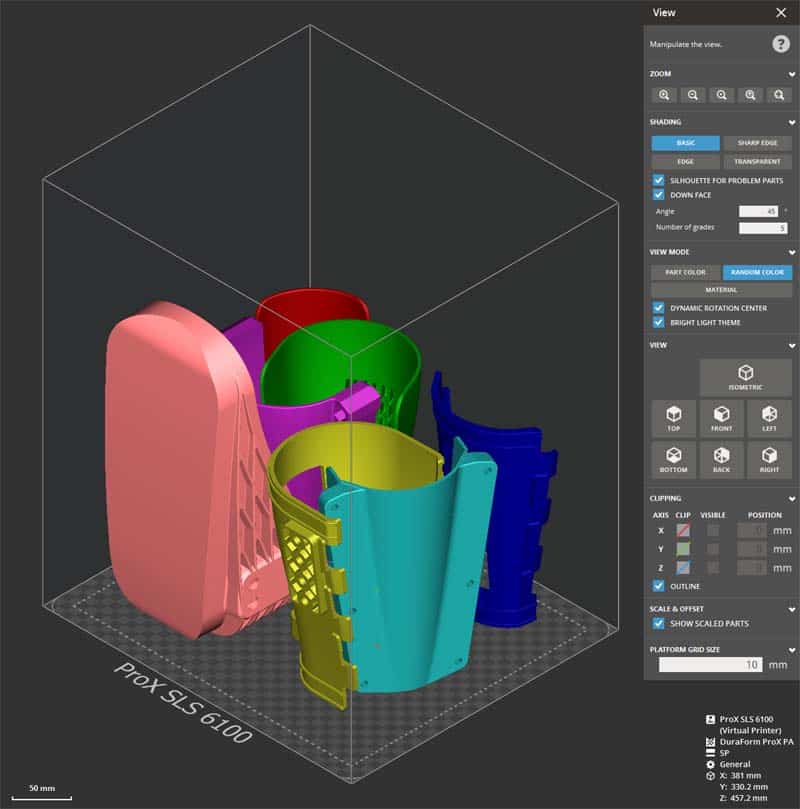

High-throughput of medium-sized parts

Our SLS printers have high-throughput of medium-sized parts (up to 330mm long) in the broadest range of thermoplastic, composite and elastomeric materials available in Selective Laser Sintering (SLS).

This printing process produces durable parts for a multitude of applications such as housings, machinery components, complex end-use parts such as ducting, functional test parts and assemblies as well as healthcare products and tools.

Tech Specs

- Max build envelope capacity (W x D x H): 15 x 13 x 18 in (381 x 330 x 460 mm)

- Broad range of production-grade nylon 11, nylon 12 , TPU, and reinforced materials

- Consistent mechanical properties

- High production speed

- Maximized build volume and density

Machines

- 3D Systems ProX 6100

- 3D Systems sPro 60

Applications

SLS uses production-grade materials, resulting in durable, functional parts that last. In fact, SLS printed parts rival other parts produced using traditional manufacturing methods.

The robustness of SLS makes this technology great for:

- Selective Laser Sintering - SLS

- Production and prototype parts that need to withstand high-heat environments or chemical exposure

- Impact resistant parts

- Parts with snap fits/living hinges

- Automotive design

- Low-volume production and mass customizations solutions

- Medical devices

- Jigs, fixtures and tools

- Aerospace parts and ducting, flame-retardant parts

- Motorsports

- Investment casting patterns

- Elastomeric and urethane parts, such as gaskets, seals and hoses

Materials

DuraForm EX (Natural)

Tough Natural Colored Nylon 11

Tough and durable polypropylene-like thermoplastic for prototypes and end-use parts requiring molded-part performance.

-

Flexible / durable

-

High elongation

-

High impact strength

Benefits

-

Ideal for snap-fit and living hinges – plastic parts that are flexible enough to fold over 180° and bounce back to their original shape

-

Parts have toughness required to replace injection molded ABS and polypropylene

-

Functional parts can be tested in real life environments such as crash tests or other stress simulations

Applications

-

Tough and durable prototypes

-

Low to mid volume direct manufacturing of end-use parts

-

Complex, thinly-walled ducts

-

Aircraft and motorsports parts

-

Enclosures and housings

-

Parts with snap-fits and living hinges

Post Processing

Infusion dyeing available (Black, Red, Blue, Yellow, Green, Orange, and Pink)

DuraForm ProX PA

Biocompatible Nylon 12

DuraForm ProX PA Plastic is an extra-strong engineered production plastic. When it comes to producing durable functional prototypes with superior mechanical properties, DuraForm ProX PA Plastic is the top choice.

The DuraForm ProX PA Plastic material is exclusively run on our ProX 6100 Printers. The printer and material produce smoother wall surfaces and injection molding-like part quality, with resolution and edge definition that surpasses existing alternatives.

Strong, tough biocompatible material that stands up to the rigors of long term real world use, replacing traditionally injection molded articles.

-

Flexible / durable

-

High elongation High-impact strength

-

Food grade

-

Medical grade

Benefits

-

Suitable for general prototyping and end-use manufacturing

-

Food contact compliant per FDA 21 CFR §177.1500 and the Plastic Directive of the European Union (EU), No 10/2011 and (EC) No 1935/2004

-

Suitable for medical parts that require USP Class VI and ISO 10993 compliance or must be sterilized

-

Exceptional recycling rate reduces waste and decreases production costs

Applications

-

Production parts

-

Snap fits

-

Automotive design

-

Aerospace parts and ducting

-

Medical / food applications

-

Jigs / fixtures / tools

-

Covers / housings / enclosures

Post Processing

Infusion dyeing available (Black, Red, Blue, Yellow, Green, Orange, and Pink)

DuraForm PA

Nylon 12

Polypropylene-like, Tough and Durable, Bio-Compatible

A Durable thermoplastic with balanced mechanical properties and fine-feature surface resolution for real world functional testing and low to mid-volume production runs. Capable of meeting USP Class VI.

Benefits

-

Suitable for general prototyping and end-use manufacturing

-

Food contact compliant per FDA 21 CFR §177.1500 and the Plastic Directive of the European Union (EU), No 10/2011 and (EC) No 1935/2004

-

Suitable for medical parts that require USP Class VI and ISO 10993 compliance or must be sterilized

-

Exceptional recycling rate reduces waste and decreases production costs

Applications

-

Prototypes that require good durability and strength

-

Low to mid volume direct manufacturing of end-use parts

-

Medical parts that require USP Class VI compliance or must be sterilized

-

Complex, thin-walled ducts

-

Aircraft and motorsports parts

-

Enclosures and housings

-

Parts with snap-fits and living hinges

-

Automotive dashboards, grilles and bumpers

Post Processing

Infusion dyeing available (Black, Red, Blue, Yellow, Green, Orange, and Pink)

DuraForm TPU

Elastomeric

Thermoplastic Durable elastomer with good tear resistance, surface finish and feature detail. Shore A hardness can be varied without changing material.

Elastomeric / rubber-like High elongation

Benefits

-

Durable thermoplastic urethane material

-

Rubber-like flexibility for prototyping and production

-

Tear and abrasion resistant

-

Prototyping and production of footwear components

Applications

-

Production parts

-

Gaskets, seals and hoses

-

Footwear

Post Processing

Infusion dyeing available (Black, Red, Blue, Yellow, Green, Orange, and Pink)

Biocompatibility information

A number of our plastic materials are ISO-10993 or USP Class VI capable. A selection of DuraForm plastic materials have met the requirements of ISO 10993-5, -10 or USP Class VI testing.

The materials listed below are ideal for:

- 3D printing of dental and orthopedic surgical guides

- 3D printing of one day crown prep guides

- Use of parts in other medical applications

| Materials | Documents | Printers |

|---|---|---|

| DuraForm PA | 3D Systems sPro 60 | |

| DuraForm ProX PA | 3D Systems ProX 6100 |

DISCLAIMER: It is the responsibility of each customer to determine that its use of any USP Class VI or ISO 10993 certified material is safe, lawful and technically suitable to the customer’s intended applications. Customers should conduct their own testing to ensure that this is the case.