Stereolithography (SLA)

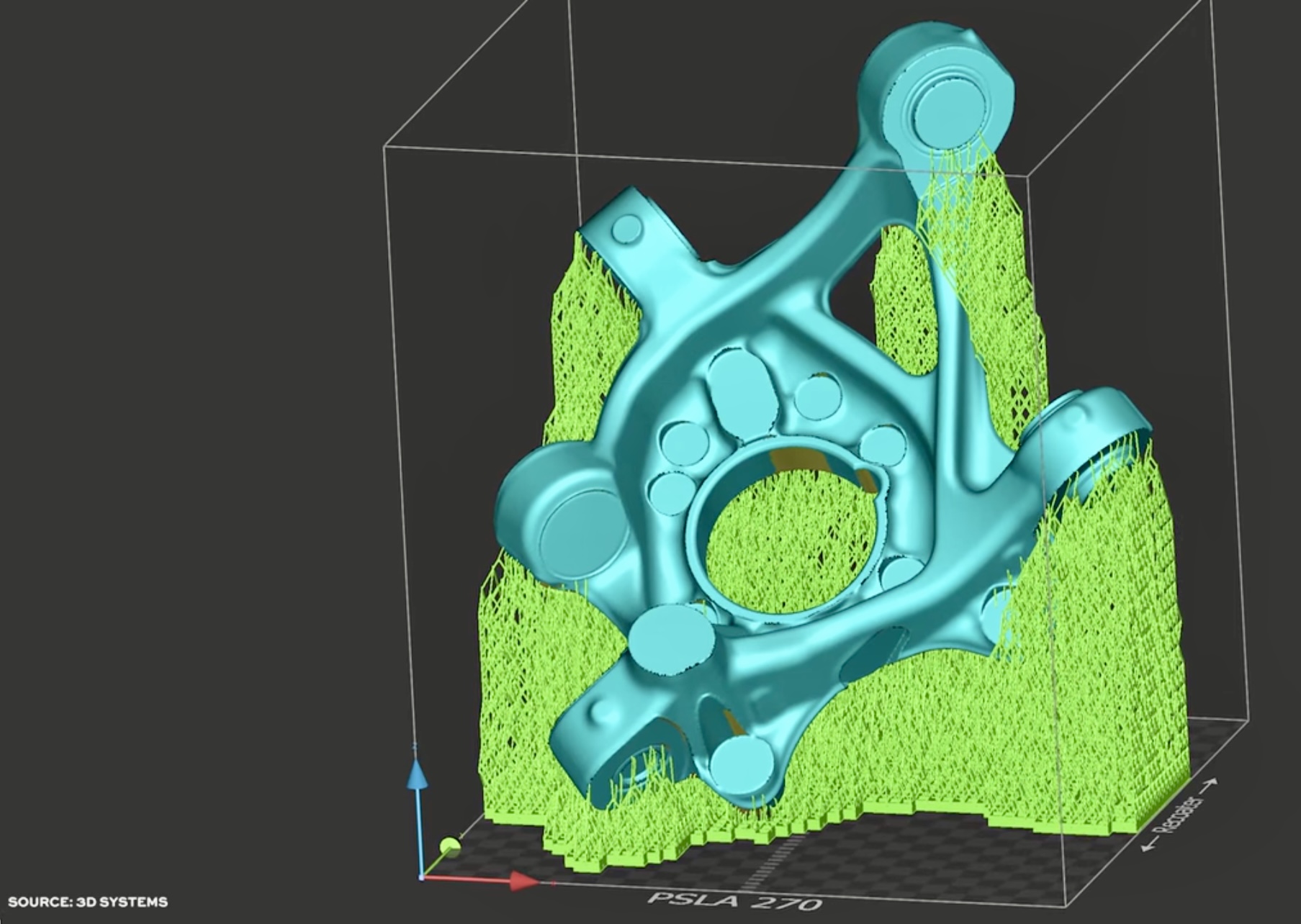

Stereolithography is the process of using an ultraviolet laser to cure photopolymers.

This process transforms the liquid photopolymers into a precision solid by building the parts, layer by layer directly from the CAD model & data.

One of the 1st forms of commercial additive manufacturing, the technology dates back to the early 1980’s.

Overview

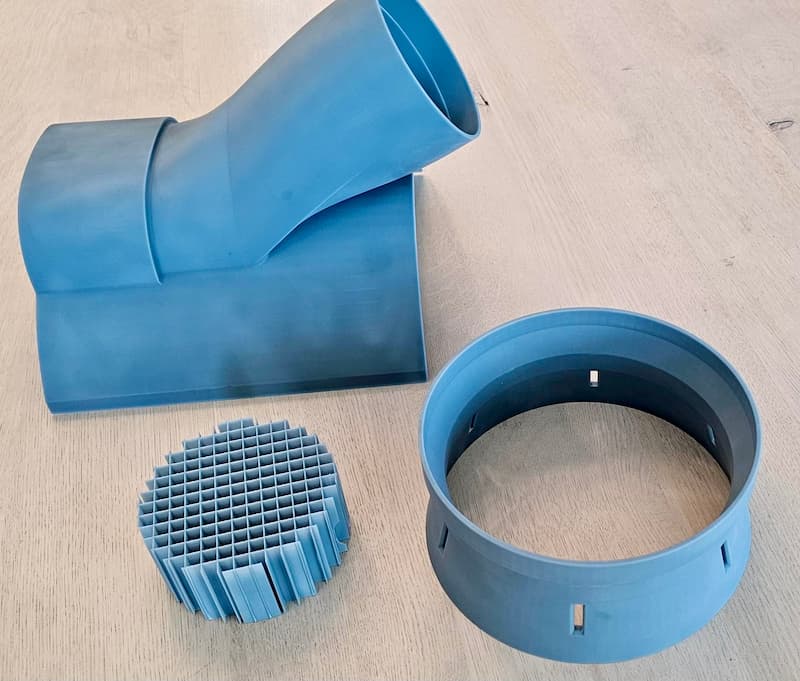

SLA is arguably the choice when a high level of precision & accuracy are needed for parts requiring critical form & fitment.

With tolerances under 0.05mm this degree of precision lends to a completed part w/ surface finishes that rival other forms of additive manufacturing.

Velocity is also a trait of SLA when you require a variety of prototypes that are not only have high precision tolerance threshold but also need to be functional in real world conditions. With SLA’s numerous advantages look to this technology to leverage rapid prototype development, identification of manufacturing challenges pre-production and low to mid volume real world production w/o the need & expense of hard tooling.

General applications for SLA:

- Wind-tunnel test models

- Complex assemblies

- Heat / extreme environment adapted applications "under the hood parts"

- Transparent, high clarity componentry & parts

- Precision functional prototypes for fitment, form testing and evaluation

Tooling applications for SLA:

- Pattern formation

- Investment casting

- Vacuum casting

- Sand casting

- Urethane casting

- Injection molding

- Fixtures & jigs requiring custom assembly

- Molds, dies & tooling

Medical Devices & support (biocompatible materials):

- Microfluidic device design & production

- Patient specific anatomical models for surgical team training & implementation

- Custom prosthetics & orthotics

- Dental tools & fixtures

- Hearing aids

- Medical valve assemblies