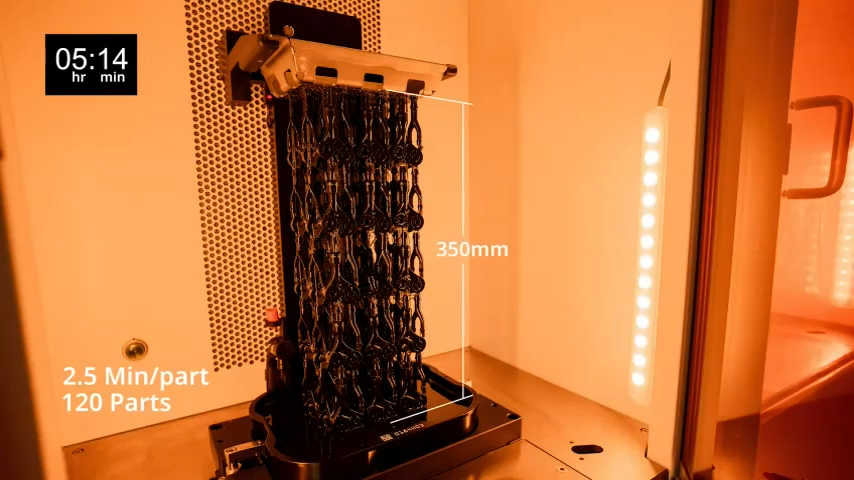

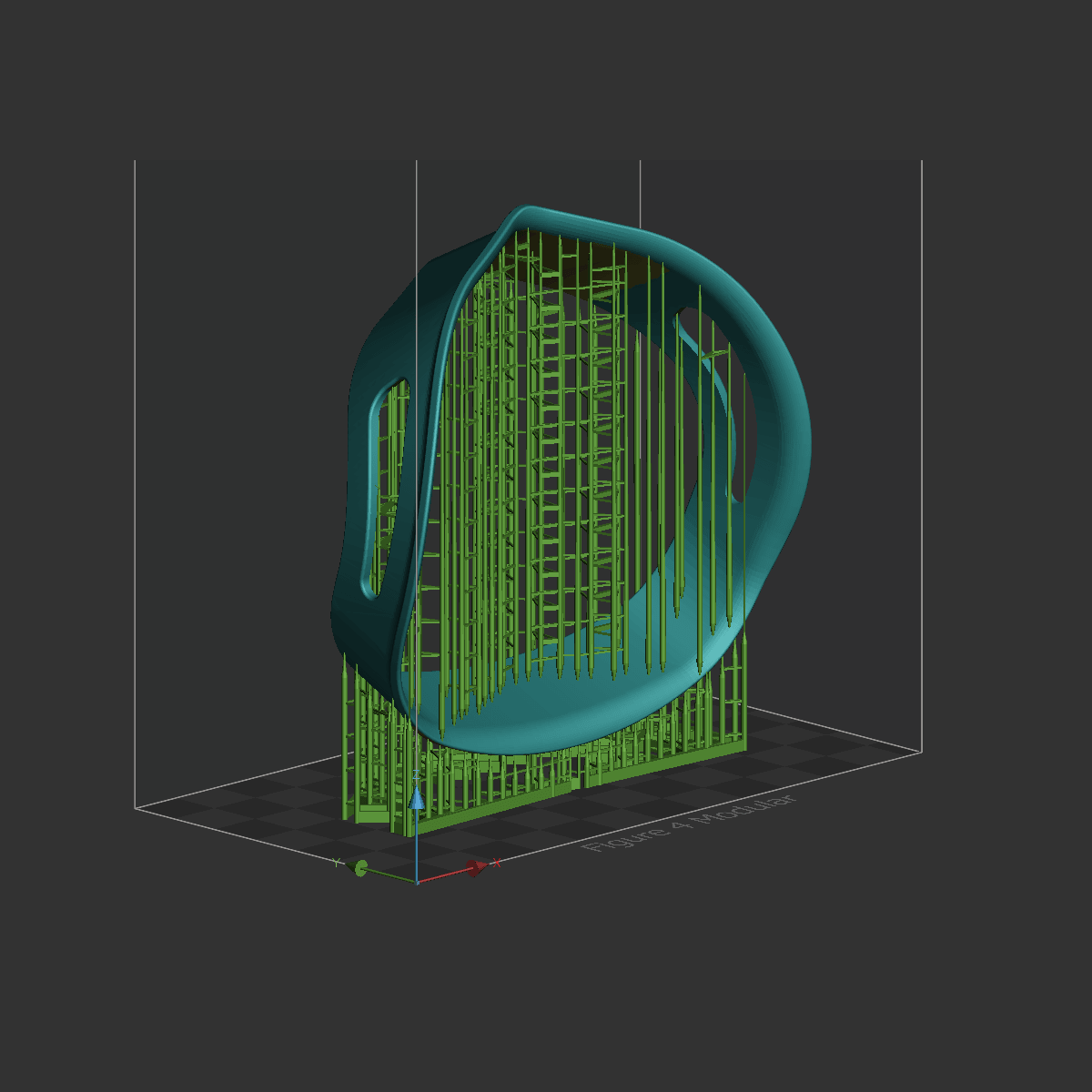

Figure 4 Production

The ATAG Incorporated Figure 4 3D printers can produce high-quality parts in a fraction of the time that traditional mold manufacturing would take.

Our factory printing solutions are unique, and that they’re scalable — a single Figure 4 module can print out quick prototypes or handle low-volume production.

Applications

Our 3D printing services are ideal for just about any application that requires efficient, single part, or on-demand production.

Produced designs are high-quality and repeatable with smooth surfaces. You can choose from a wide range of materials (outlined below) to suit your project. Here are some of Figure 4’s most common applications:

- Production of fully isotropic parts

- Fast creation of prototypes

- Short production runs of plastics

- Production of transparent, highly heat-tolerant parts

- Replacing cast urethane and molding production methods

- Developing master patterns and molds for rapid tooling

- Creation of fixtures and jigs

- Production of end-use plastic parts

- Low-volume manufacturing

Materials

Figure 4 PRO-BLK 10

For a quick, easy production experience, our PRO-BLK 10 is the answer. This polypropylene-like material is versatile and heat-resistant, and it is environmentally stable in indoor and outdoor environments.

PRO-BLK 10 parts can be manufactured quickly — we can produce parts the same day, and our finishing process is quick and straightforward. And even though the production of PRO-BLK 10 is fast, this material is long-lasting and durable.

Benefits

- Accurate materials produce a successful print on the first try

- Simplified cleaning and finishing let it ship quickly

- Parts are highly environmentally stable

Applications

- Ideal for producing small, general-use plastic parts like connectors or interior car parts

- Parts can be assembled and shipped on the same day

- A good replacement option for injection molding manufacturing

- Print speed is fast at 62 mm/hr for a thickness of 50 microns

- Indoor and outdoor environmental stability is long-term

- Has heat deflection temperature of 70 degrees Celsius and a 12% elongation at break

TOUGH-GRY 10

Benefits

- Rigid parts remain stable over time

- Dark gray parts can be plated or painted as necessary

- Production speed is rapid

Applications

- TOUGH GRY-10 produces solid parts

- Ideal for snap fits, covers/cases, and parts for automotive styling

- Suitable for parts that need to be painted or otherwise finished upon arrival

- Can reach a print speed of 100 mm per hour

- 25% elongation at break makes it very durable

- Heat deflection temperature at 59 degrees Celsius (at 0.45MPa)

TOUGH-GRY 15

Benefits

- It is priced very affordably

- Accurate and durable components are very reliable

- Material remains highly stable over time

Applications

- Ideal for short runs of plastic parts

- High accuracy makes them great for snap fits, cases, and more

- The surface takes well to plating or painting

- Heat deflection at 59 degrees Celsius (at 0.45MPa)

- Has 35% elongation at breaking point

- The standard print speed is approximately 41 mm/hr at 0.05 mm.

Figure 4 TOUGH-BLK 20

Benefits

- It offers the quality of injection-molded parts without the time or cost

- It’s more environmentally stable than most cheaper materials

- It has exceptionally smooth surfaces

Applications

- It produces rigid parts ideal for short-run production

- It’s durable enough to make components of consumer electronics

- Precise, robust quality makes it great for snap-fits

- Heat deflection temperature is 55 degrees Celsius (at 0.45MPa)

- Has 36% elongation at break

- The standard print speed is approximately 43 mm/hr with 0.05 mm thickness.

Figure 4 RUBBER-BLK 10

Benefits

- Smooth, high-quality surface finish ideal for higher-end products

- It is both sturdy and highly tear-resistant

- Suitable for a range of soft-touch coatings

Applications

- Tough enough to be used for couplings

- Suitable for manufacturing any part that requires reliable environmental stability

- Hard, slow-rebound material works well for bumpers, grips, and similar applications.

- Exceptional 80% elongation at breaking point

- Print speed of 26mm/hr with 0.03 mm thickness

- Tear strength of 76 kN/m

Figure 4 RUBBER-65A BLK

Benefits

- It is a relatively affordable material

- The medium-hard rubber material is very versatile

- It’s effortless to clean

Applications

- Suitable for making gaskets and seals

- Great for making slightly softer grips

- A good choice for pipe spacers

- Tear strength of 8.5 kN/m

- The standard production speed is 15 mm/hr at a thickness of 50 micrometers

- Offers 126% elongation at break

Figure 4 FLEX-BLK 20

Benefits

- High-quality parts with very smooth surfaces

- Very robust, fatigue-resistant material

- More environmentally stable than many similar materials

Applications

- Great for making high-quality cases and enclosures

- A good choice for design prototypes or silicone molding master patterns

- Good for electronics components

- The standard speed of 25 mm/hr at 0.05 mm thickness

- 76% elongation at breaking point

- Heat deflection temperature is 41 degrees Celsius at 0.455 MPa.

Figure 4 HI-TEMP 300-AMB

Benefits

- Rigid, highly heat-resistant material will stand up to high stress

- Translucent plastic is excellent for visualization

- It does not require a secondary thermal post-cure

Applications

- Ideal for use in HVAC, consumer electronics, and other applications involving high heat

- Good for overmolding

- A good choice for low-pressure molding and tooling

- Has 2.6% elongation at breaking point

- Heat deflection temperature is over 300 degrees Celsius at 0.455 MPa

- The standard production speed is 36 mm/hr at a 50-micrometer thickness

Figure 4 EGGSHELL-AMB 10

Benefits

- Translucent material lets you visualize the injection

- It creates excellent details for precise casting

- It can work with most silicone types

Applications

- Great for casting silicone in any durometer

- Can quickly produce quality prototypes

- Ideal for low-volume silicone parts production

- Has 5% elongation at breaking point

- Heat deflection temperature is 89 degrees Celsius at 0.455 MPa

- The standard production speed is 43 mm/hr at 0.05 mm thickness

Figure 4 MED-AMB 10

Benefits

- Can meet biocompatibility standards (ISO 10993-5 and 10993-10)

- Translucent material allows for internal feature evaluation

- Features are delivered in incredible detail

Applications

- Ideal for applications requiring visualization of fluid flow

- Suitable for use in splints and surgical drill guides

- Especially useful in creating threaded assemblies

- Has 4% elongation at breaking point

- Heat deflection temperature is 119 degrees Celsius at 0.45 MPa

- The standard production speed is 43 mm/hr at a 0.05 mm thickness

Figure 4 FLEX-BLK 10

Benefits

- It is both flexible and impact-resistant, which makes it very durable

- The polypropylene-like finish is smooth and beautiful

- It is ideal for both prototyping and short-run production

Applications

- Great for functional product design prototypes

- A good choice for silicone molding master patterns

- Great for snap-fit containers and assemblies

- Has an impressive 104% elongation at breaking point

- Heat deflection temperature is 52 degrees Celsius at 0.45 MPa

- The standard production time is 33 mm/hr at 0.10 mm thickness

Figure 4 ELAST-BLK 10

Benefits

- It recovers its shape exceptionally well after compression

- It looks and feels significantly like natural rubber

- Medium softness/stiffness makes it very versatile

Applications

- Great for validating and testing a variety of product designs

- Also good for weatherproofing and other kinds of seals

- Suitable for making hoses and tubes

- The standard production speed is 47 mm/hr at 0.10 mm thickness

- Has 83% elongation at break

- Tear strength of 11 kN/m

Figure 4 Rigid White

Benefits

- Excellent indoor and outdoor environmental stability

- The opaque white color is beautiful and doesn’t fade.

- Short turnaround time for delivering the finished product

Applications

- Great for fixtures on medical devices

- Suitable for smaller components on a variety of products

- Great for guards, covers, and snap-fit parts

- Has 20% elongation at breaking point

- Heat deflection temperature is 65 degrees Celsius

- The standard print speed is 47 mm/hr with a thickness of 50 microns

Benefits

You may be concerned about the Figure 4 printed part prices. After all, most of us keep the “triple constraint” in mind — out of fast, reasonable, and low cost; you can pick two options.

Conventional business wisdom holds that you can get a good product fast (but not cheap), a fast product cheap (but not good), or a good product cheap (but not fast). You can’t have all three.

But with the Figure 4 technology, the triple constraint is turned on its head — you get a good, low cost product quickly.

Good

Figure 4 technology creates very high-quality parts, and those results are repeatable. A test of 30 samples from Figure 4 machines discovered a process capacity index greater than two — a product that is considered six-sigma quality. It means that Figure 4 is now the industry leader in terms of accuracy.

Additionally, Figure 4 offers a wide range of some of the best materials for any application. Whether you need tear-resistant rubber, fast-printing plastic, or transparent heat-resistant parts, we likely have something for you.

Low Cost

Figure 4 technology also saves considerable money during the manufacturing process. During comparative testing of Figure 4 technology versus urethane casting, the cost per part (in this case, a dashboard vent) using Figure 4 was $7.90. The price per part with urethane casting was $35.10.

Another test found that Figure 4 manufacturing also saved money over injection molding. The estimated combined cost of CAD, tooling design, and tooling labor (for eight days) using injection molding was $4,315. For Figure 4 technology, the price was $121.

Fast

Our Figure 4 machines are among the fastest in the industry. Depending on the material used, they can print at speeds up to 100mm/hr. And they save time over the long term, too. In the above comparison with urethane casting, the first part with Figure 4 was 1.5 hours. For urethane casting, it was 156 hours. Similarly, compared with injection molding, the first part with Figure 4 was 92 minutes. With injection molding, it was 15 days.

Biocompatibility information

A number of our Figure 4 Materials are ISO 10993-5 and ISO 10993-10 capable.

Test coupons printed and processed according to the post processing instructions provide in each material specification sheet were provided to an external biological testing laboratory for evaluation in accordance with ISO 10993-5, Biological evaluation of medical devices – Part 5: Tests for in vitro cytotoxicity, and ISO 10993-10, Biological evaluation of medical devices – Part 10: Tests for irritation and skin sensitization (GPMT).

The test results indicate that Figure 4 materials have passed the requirements for biocompatibility according to the above tests.

Disclaimer

It is the responsibility of each customer to determine that its use of Figure 4 materials is safe, lawful and technically suitable to the customer’s intended applications.

Customers should conduct their own testing to ensure that this is the case. Because of possible changes in the law and in regulations, as well as possible changes in these materials, ATAG Incorporated, LLC cannot guarantee that the status of these materials will remain unchanged or that it will qualify as biocompatible in any particular use. Therefore, ATAG Incorporated, LLC recommends that customers continuing to use these materials verify their status on a periodic basis.